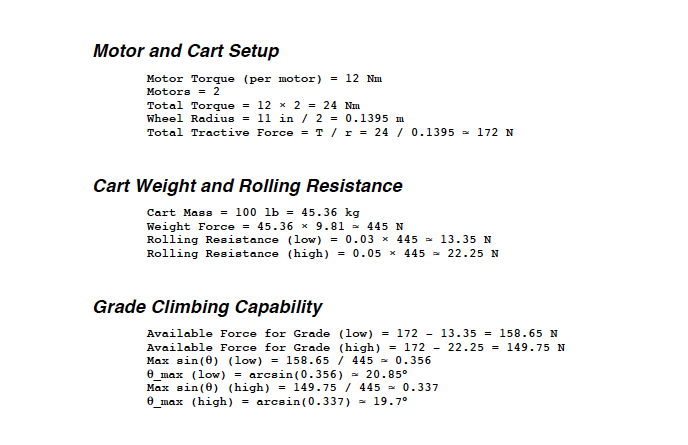

Engineering a Solution for Time Together

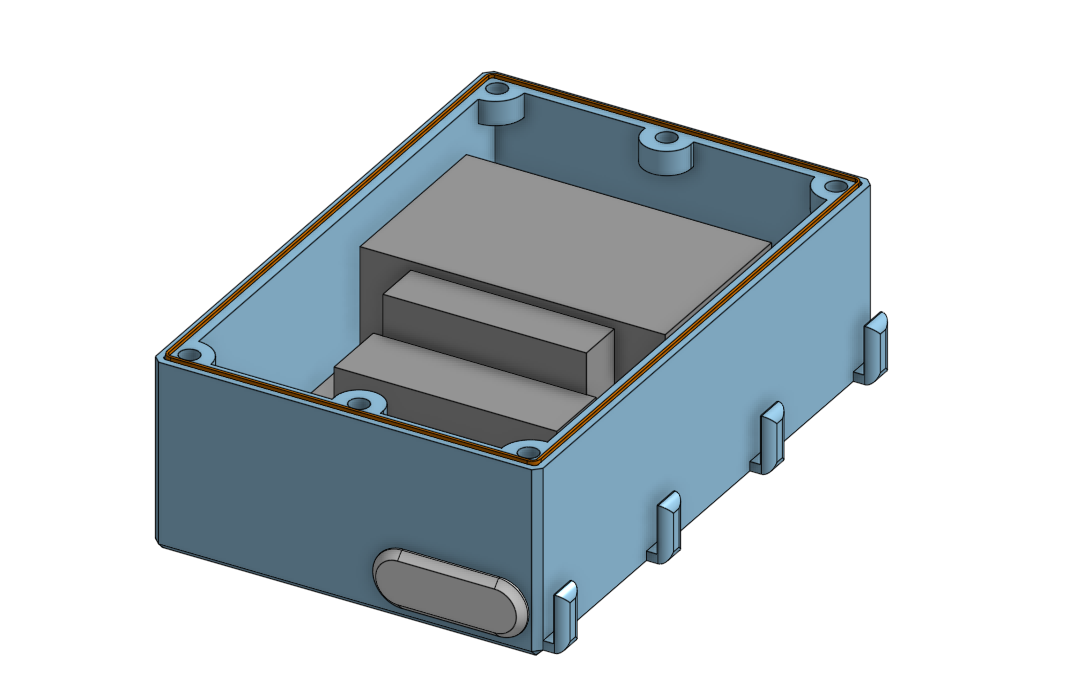

For a long time, my dad has struggled with chronic back pain. Despite that, one thing we've always loved doing together is playing golf. But his back issues made walking the course difficult, and using a powered golf cart meant we weren't spending time together. This project was born from a simple question: what if my dad could still walk the course without having to carry or push his bag?

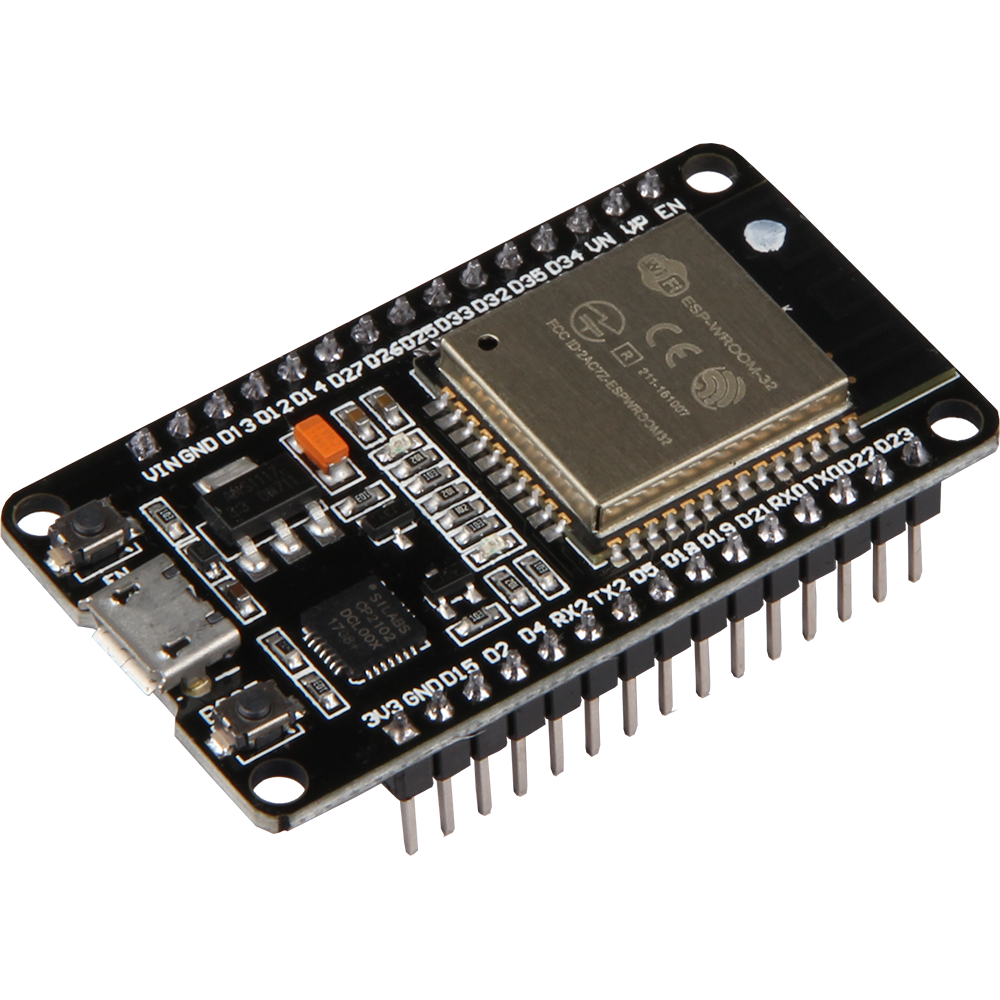

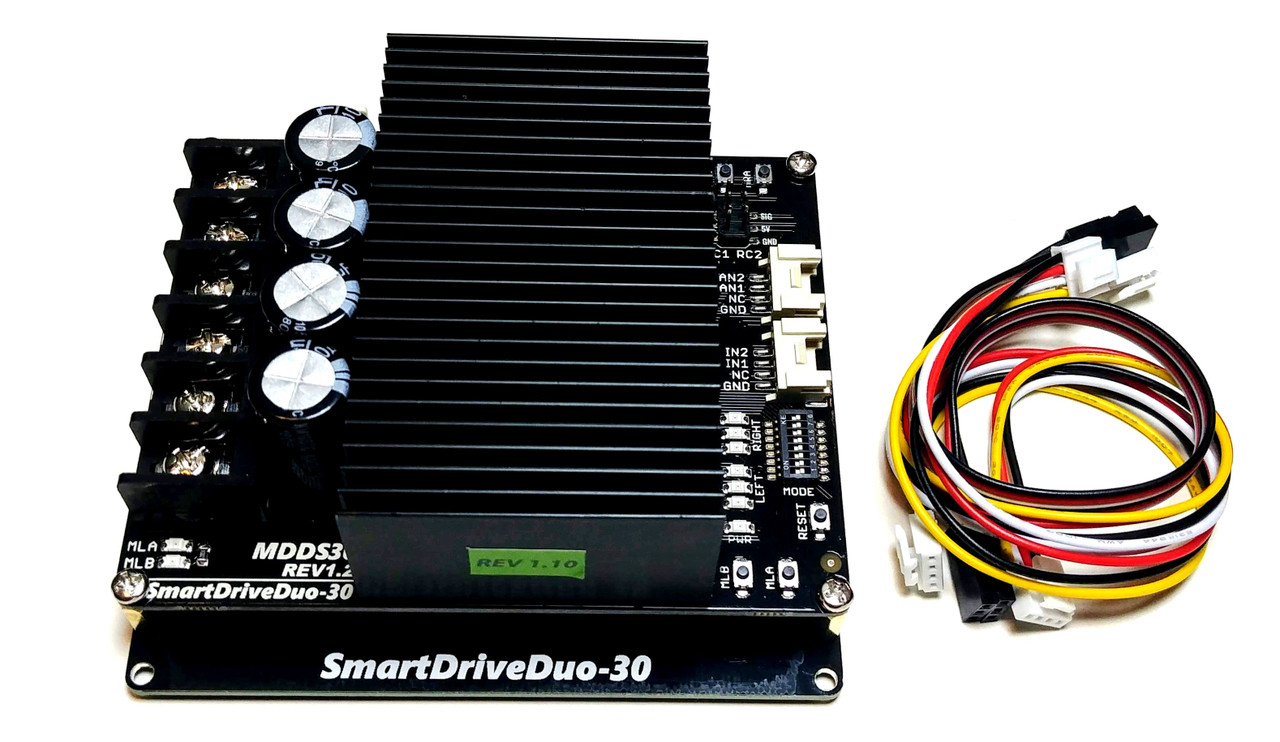

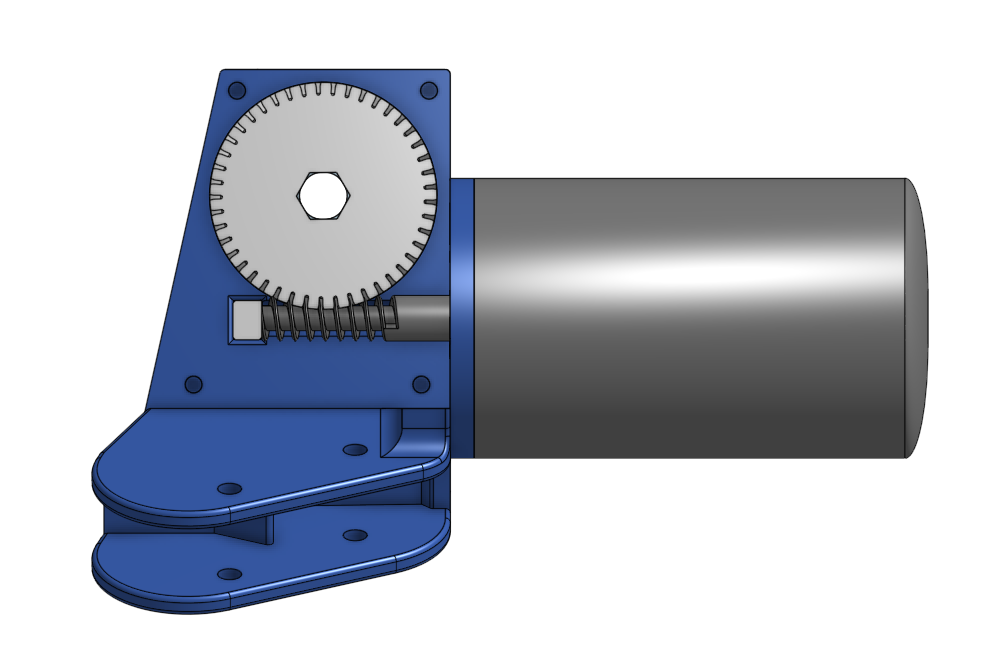

Electric Cart In Progress