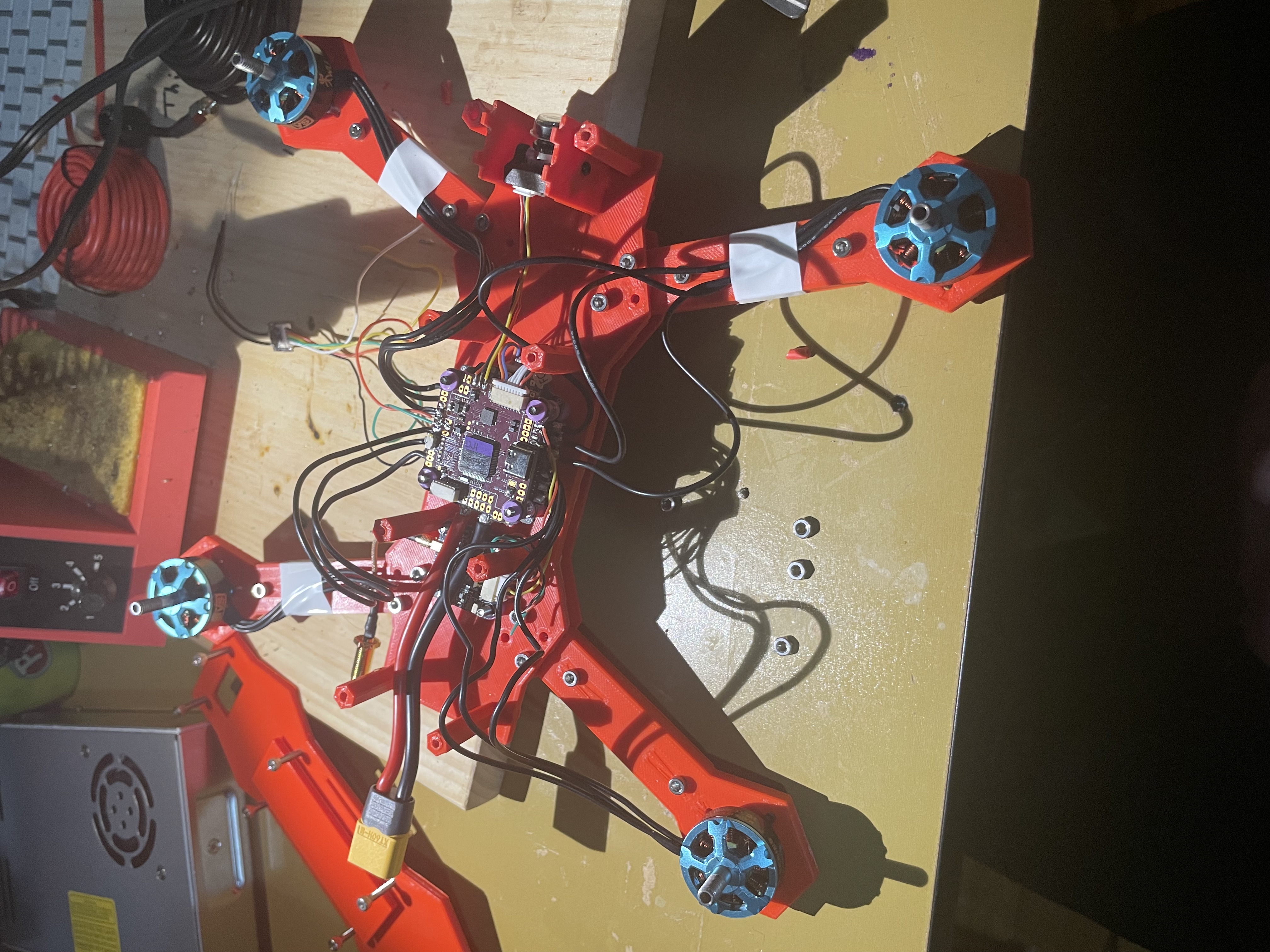

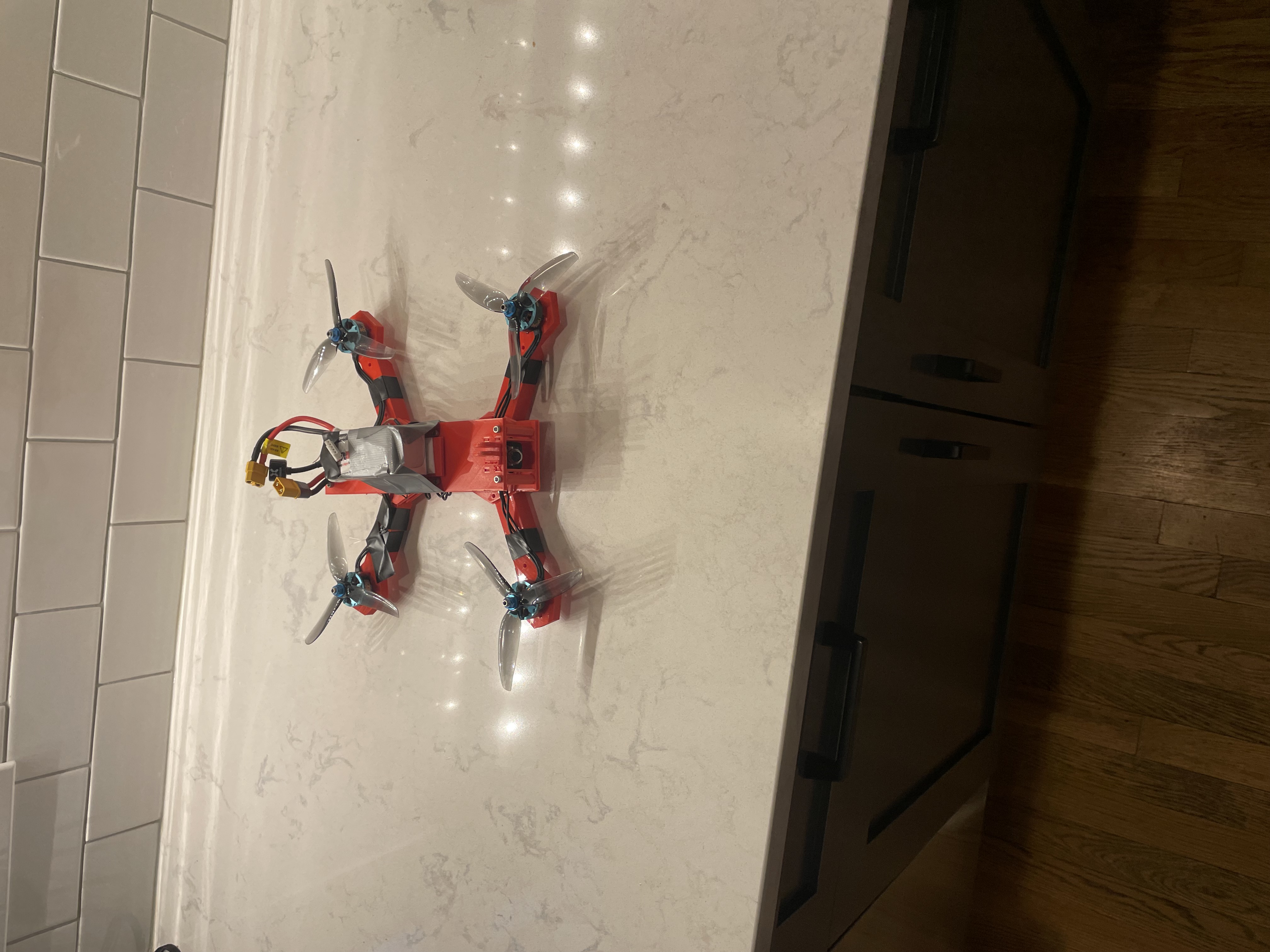

MK3 FPV Racing Drone

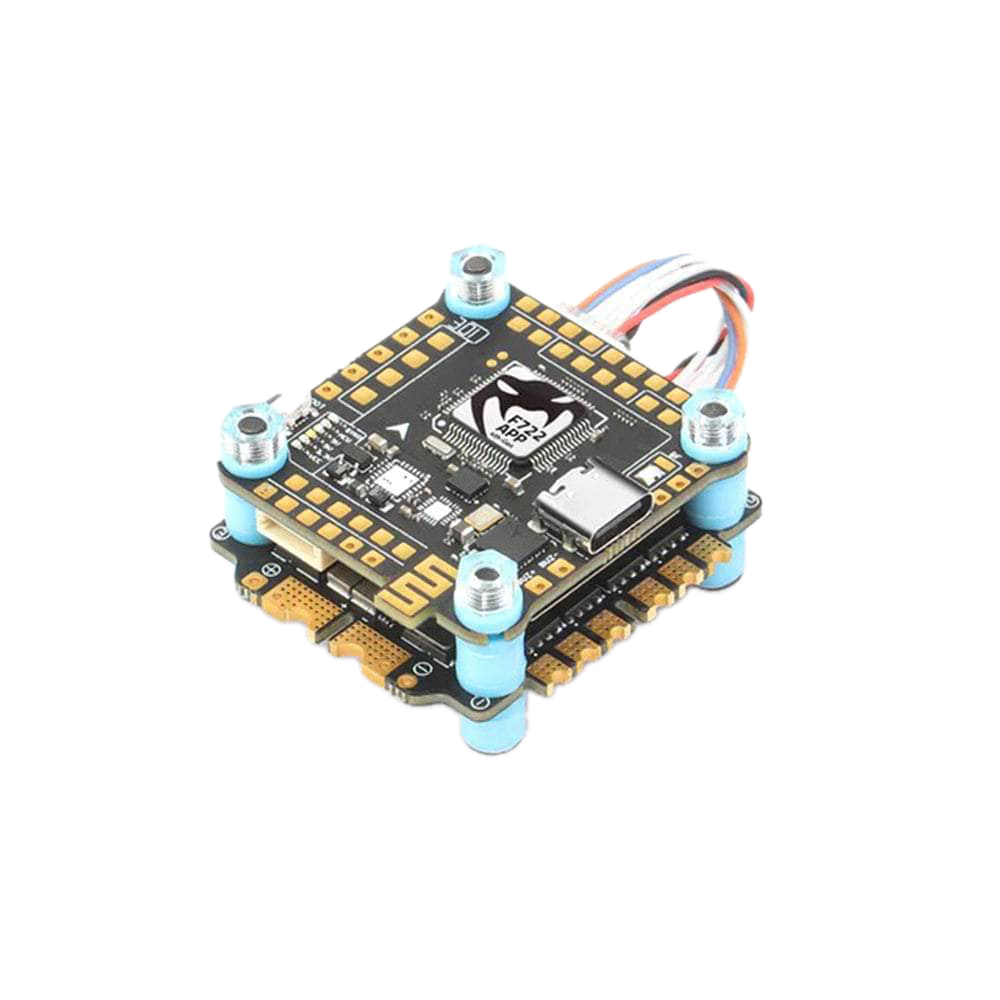

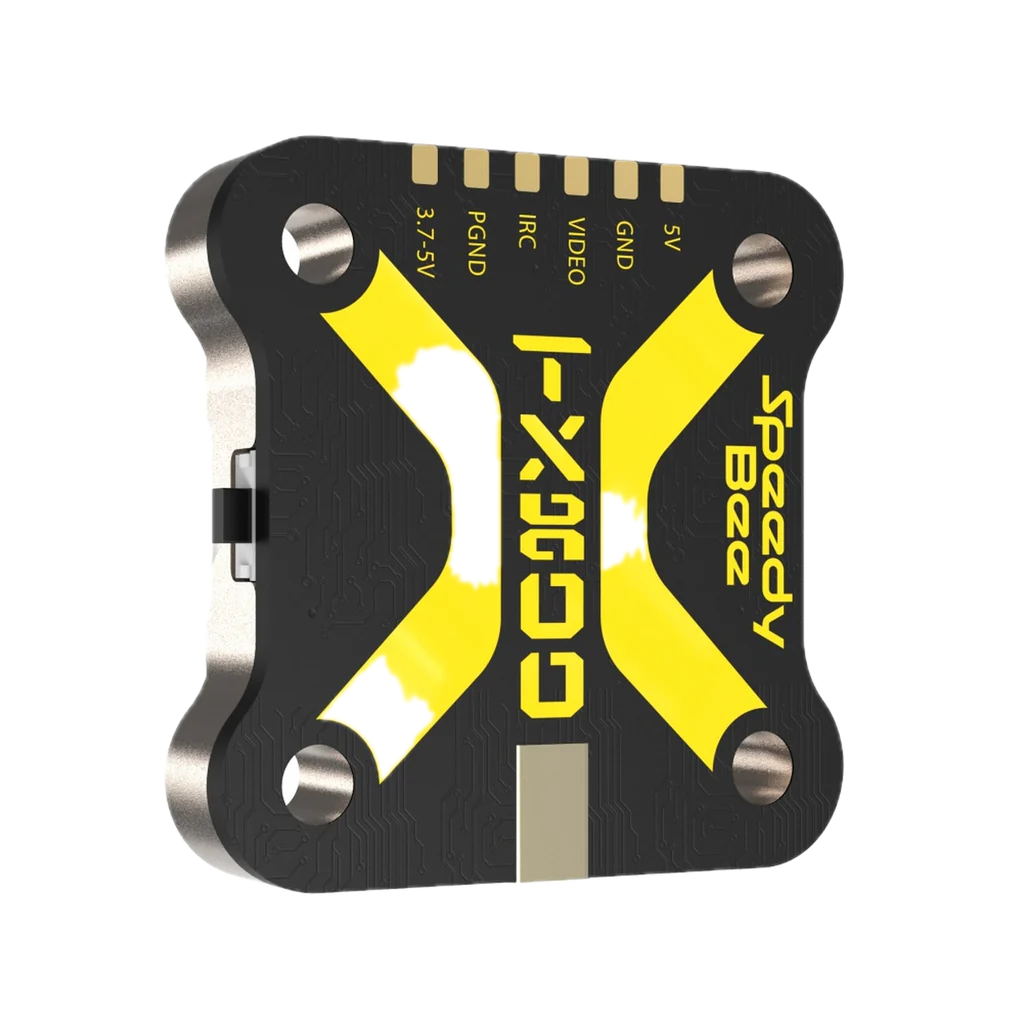

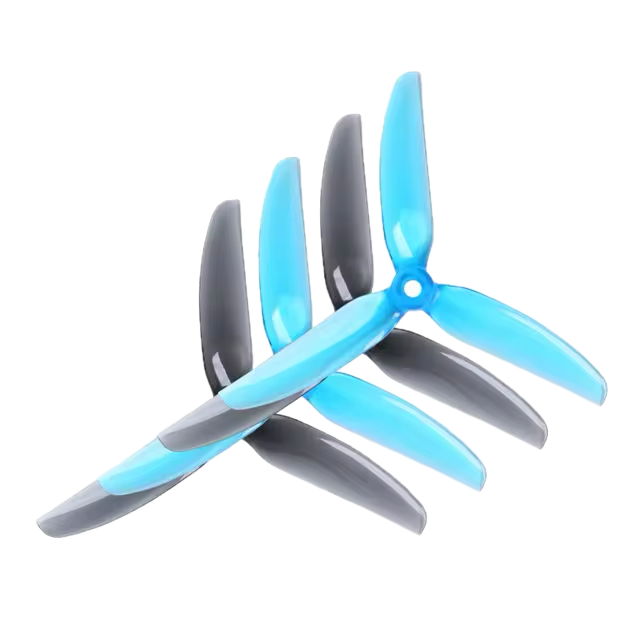

The objective of this project was to develop a low cost, durable drone frame with interchangeable parts that can be easily replaced. Frame designed to be sturdy enough to withstand a hard landing from falls of over 100ft. The drone pilot can have an immersive experience over a 3 mile (environment dependent) range and recording abilities with onboard GoPro.