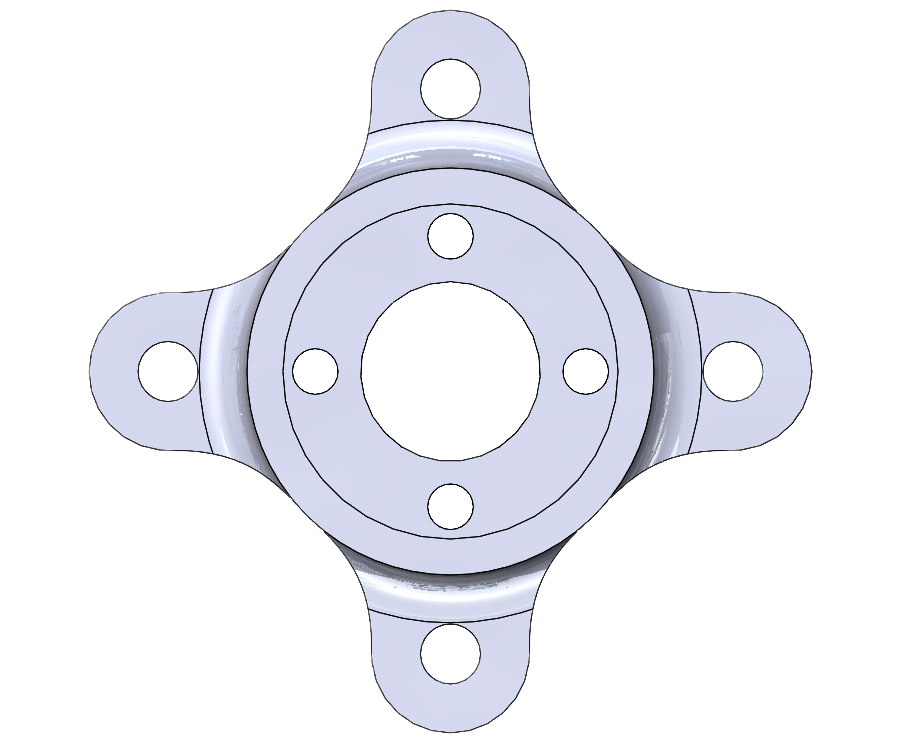

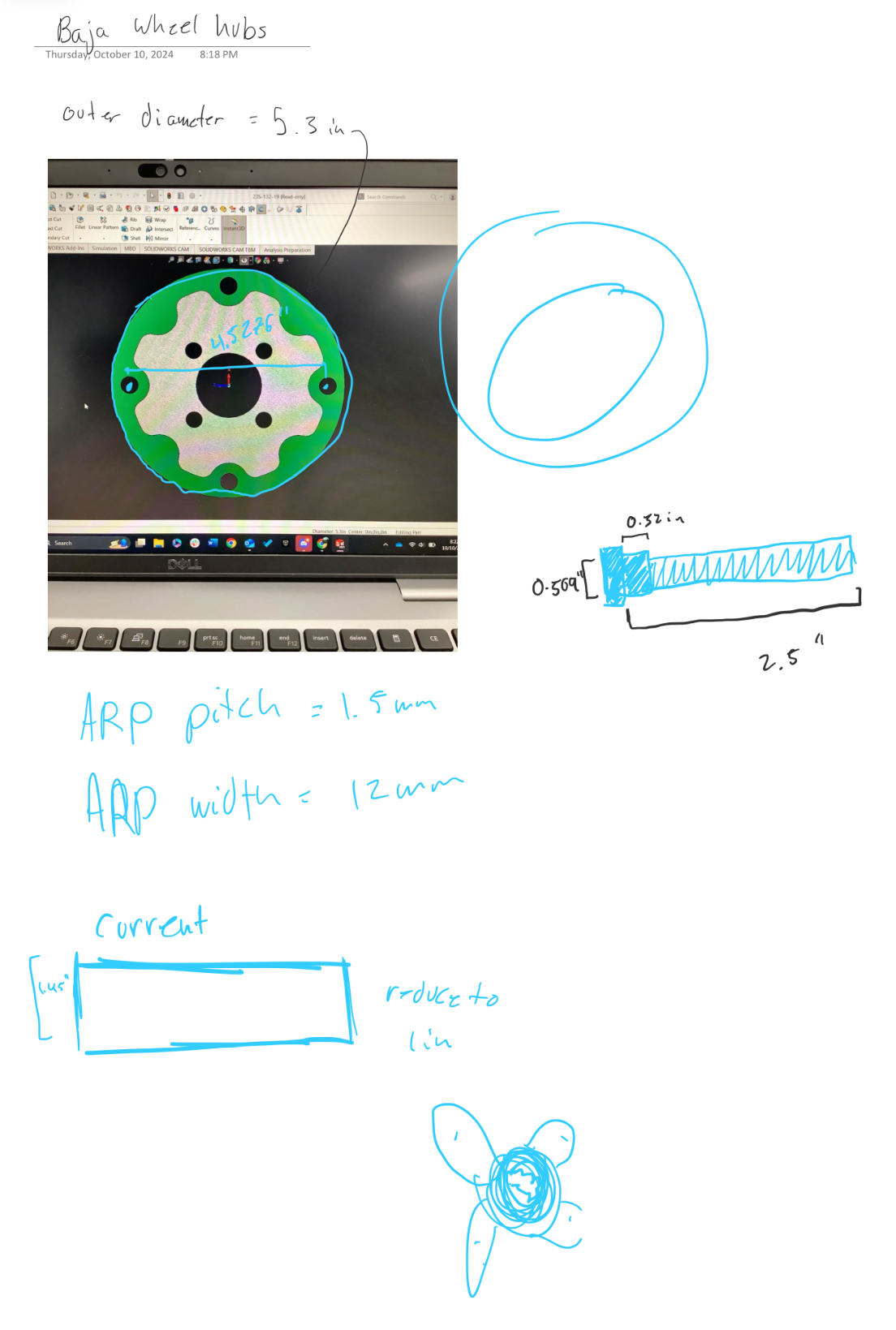

Project Overview

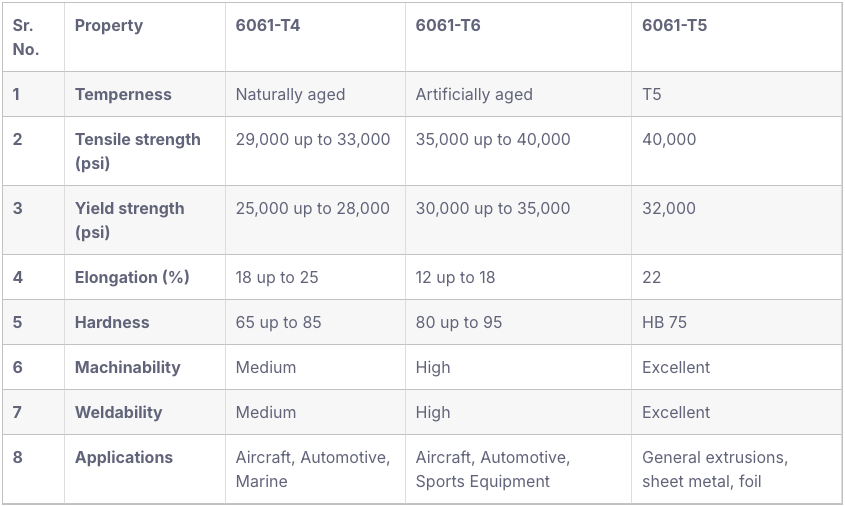

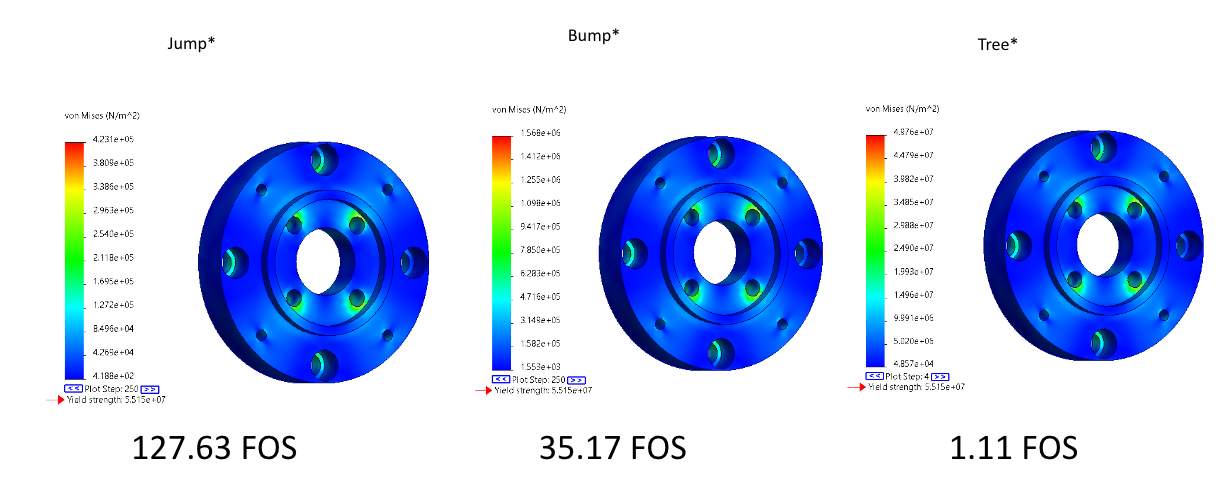

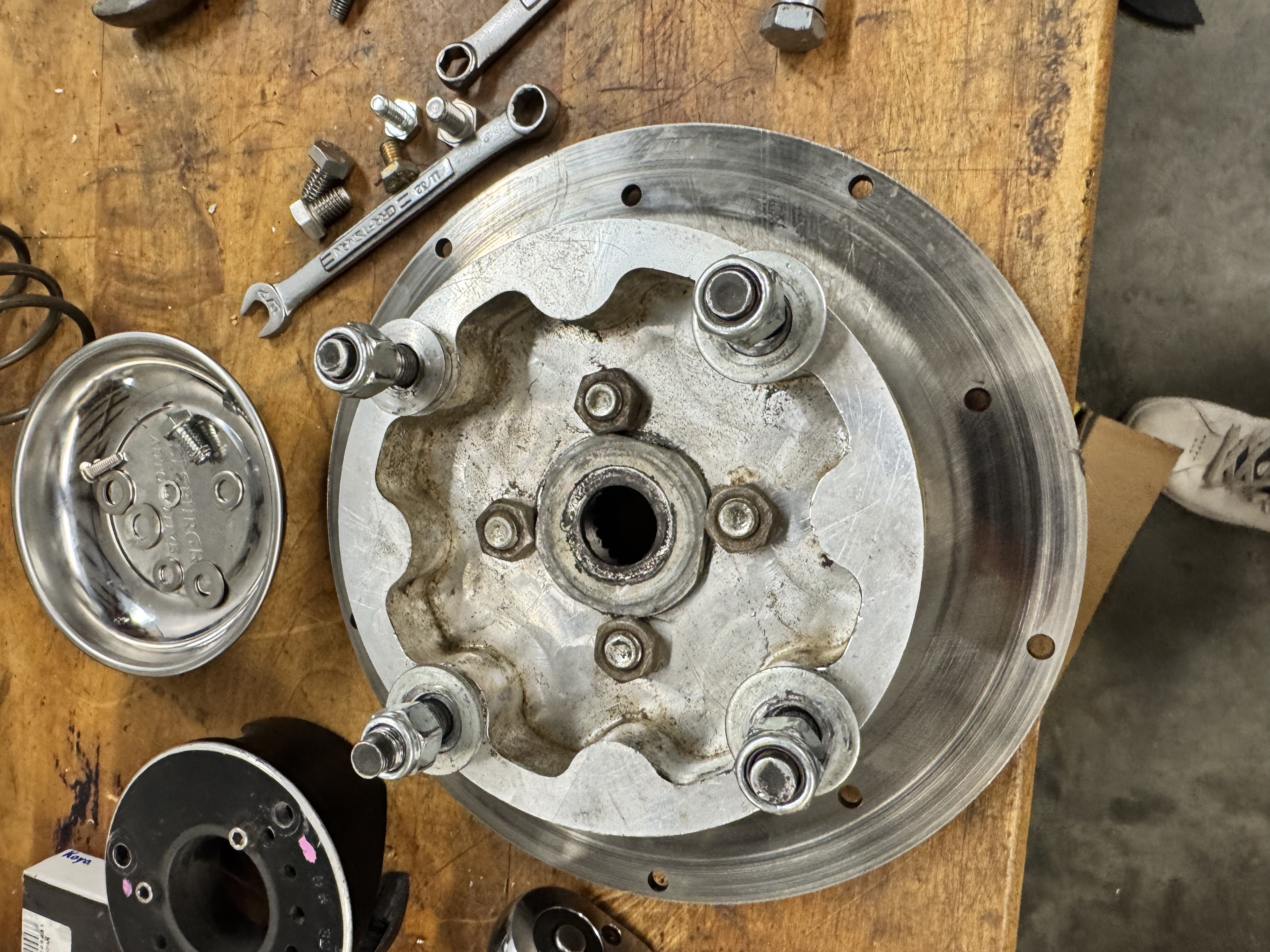

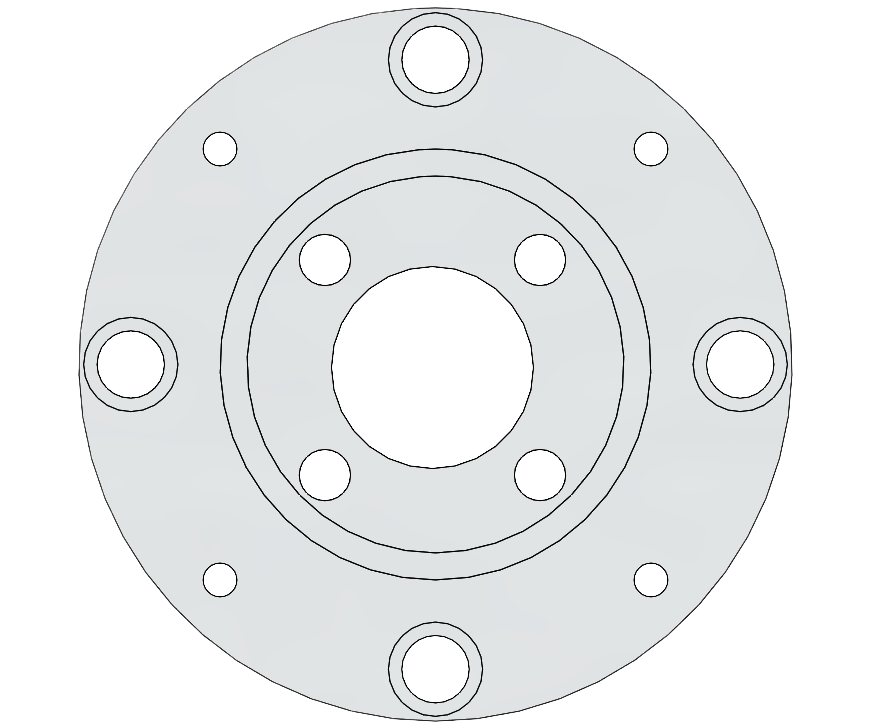

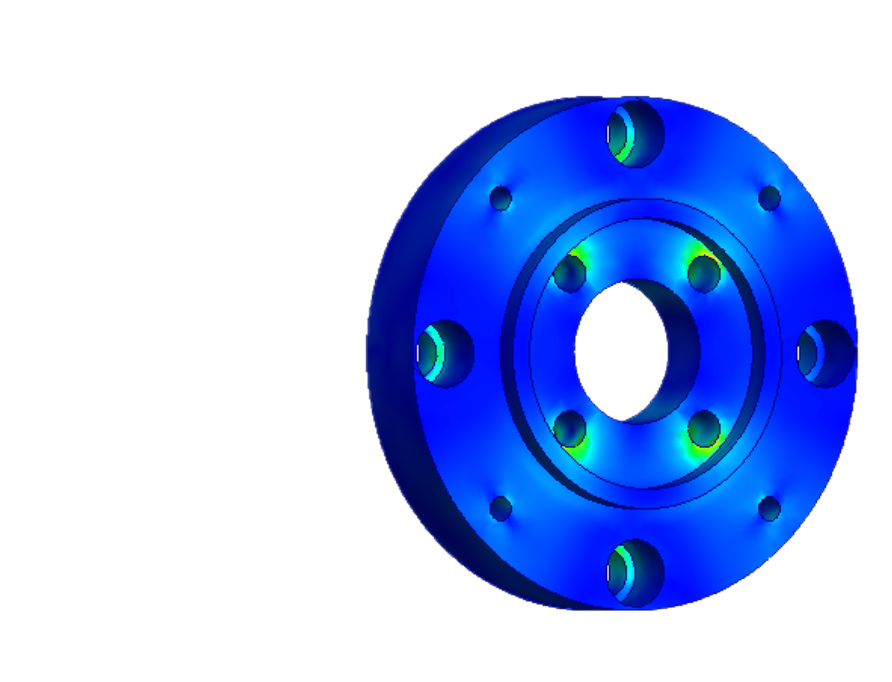

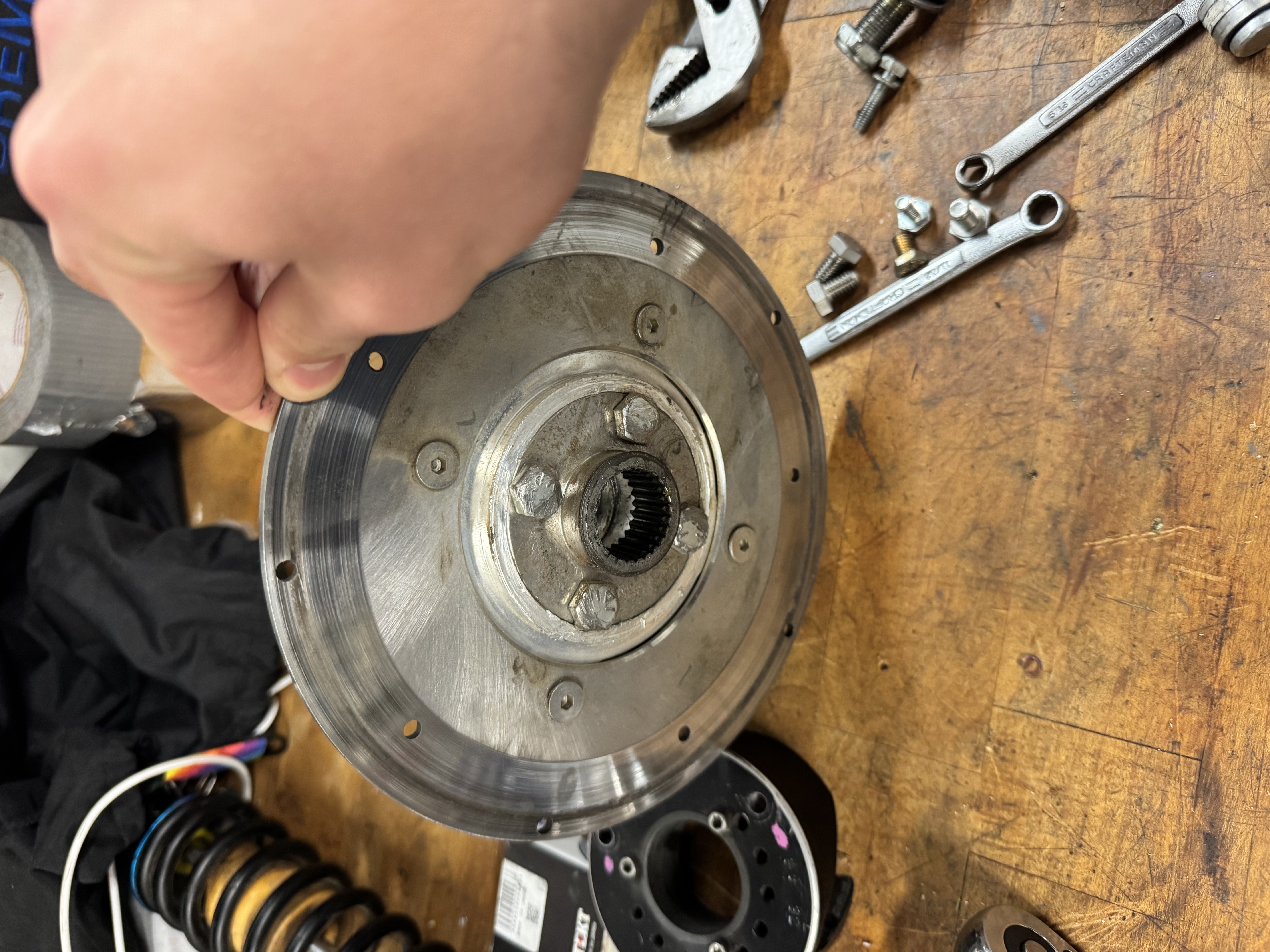

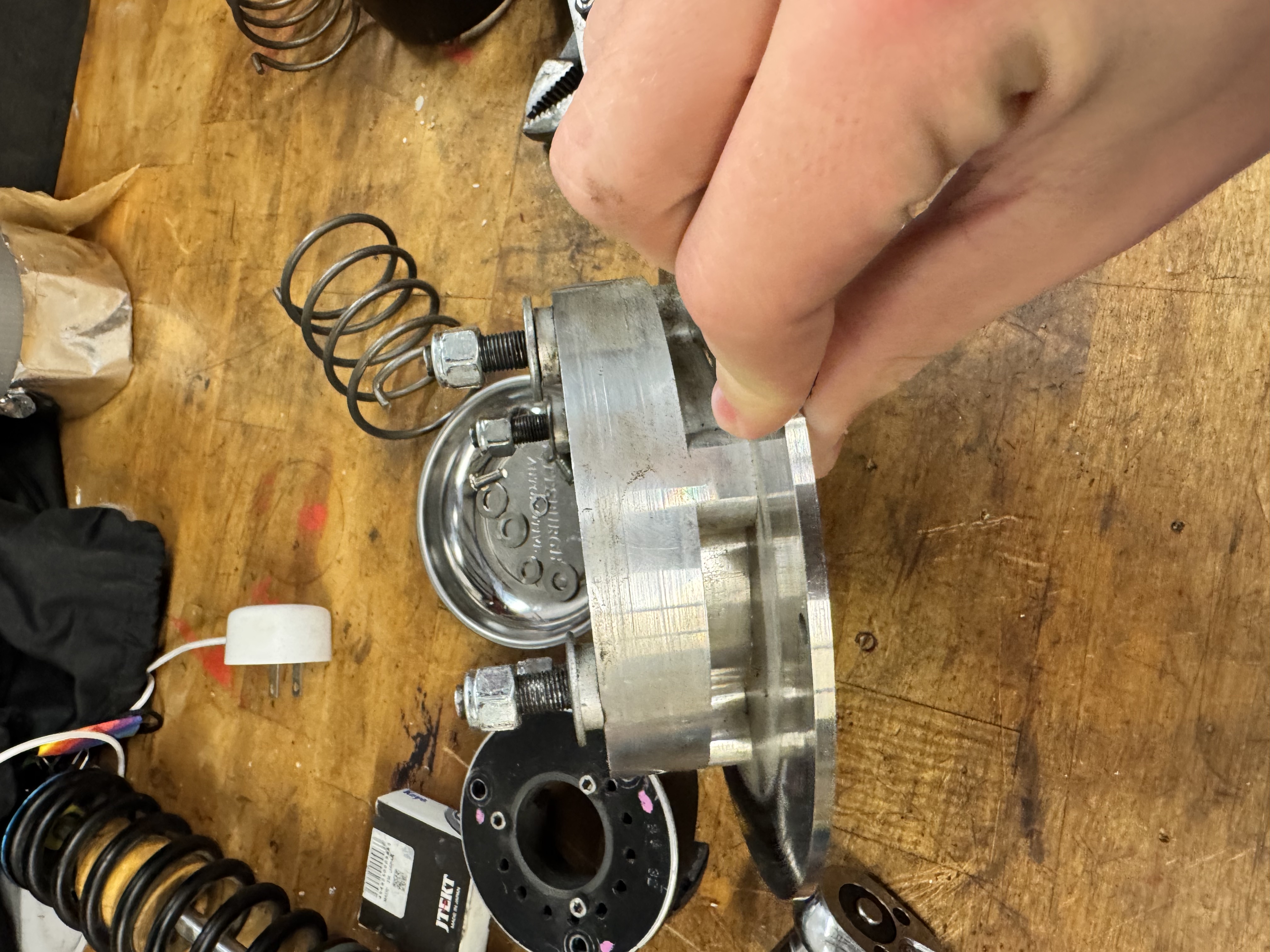

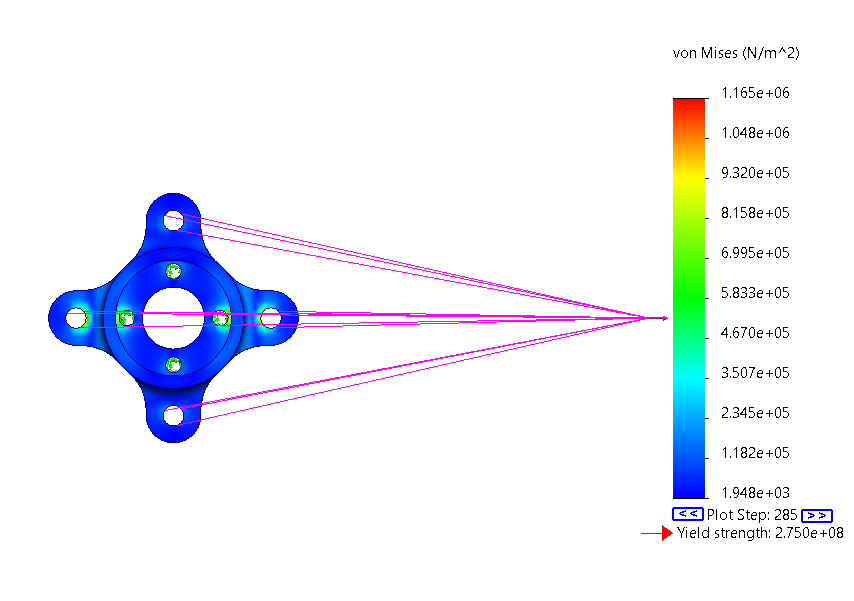

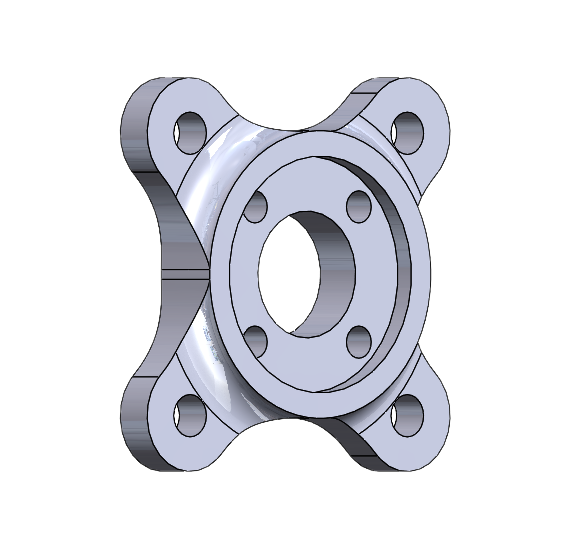

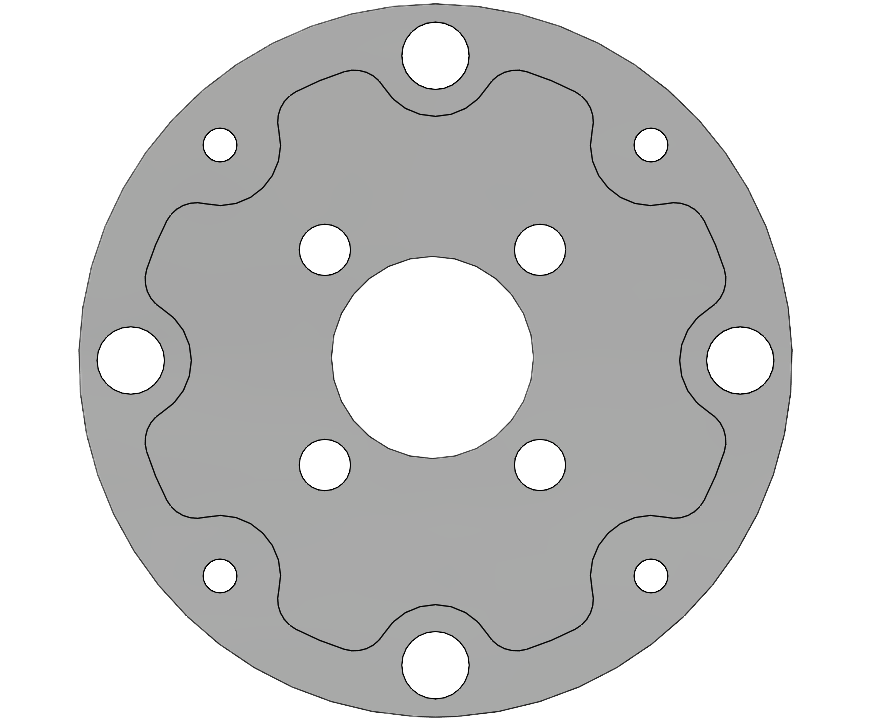

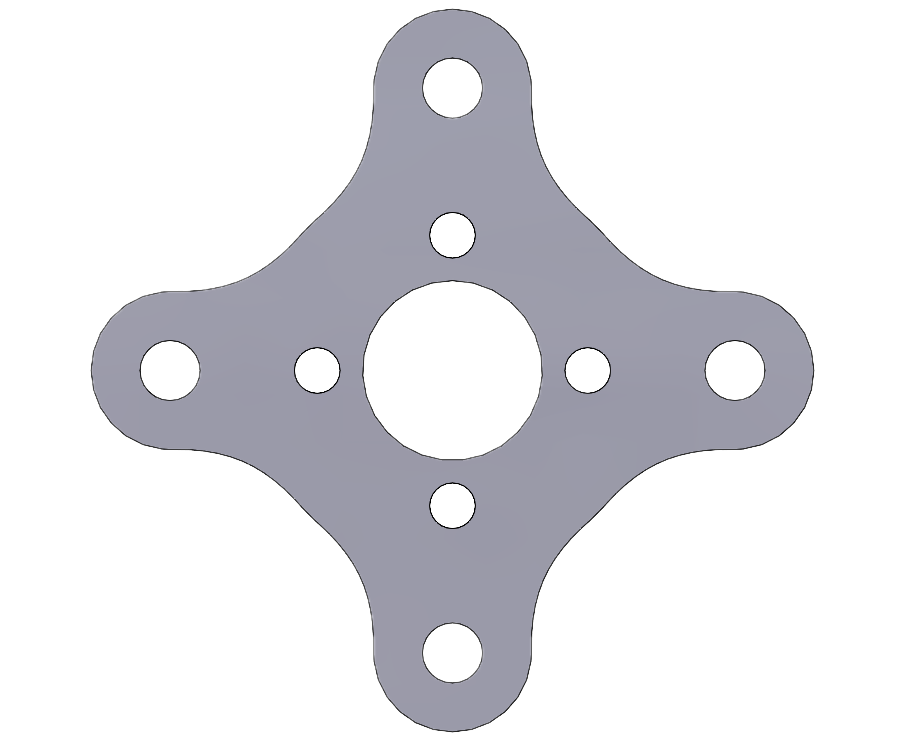

The BAJA wheel hubs redesign at Olin College of Engineering aimed to create a lighter, more efficient, and structurally optimized component for off-road racing conditions. The project focused on enhancing vehicle performance through material optimization, improved design geometry, and thorough load analysis, all while ensuring safety and reliability.