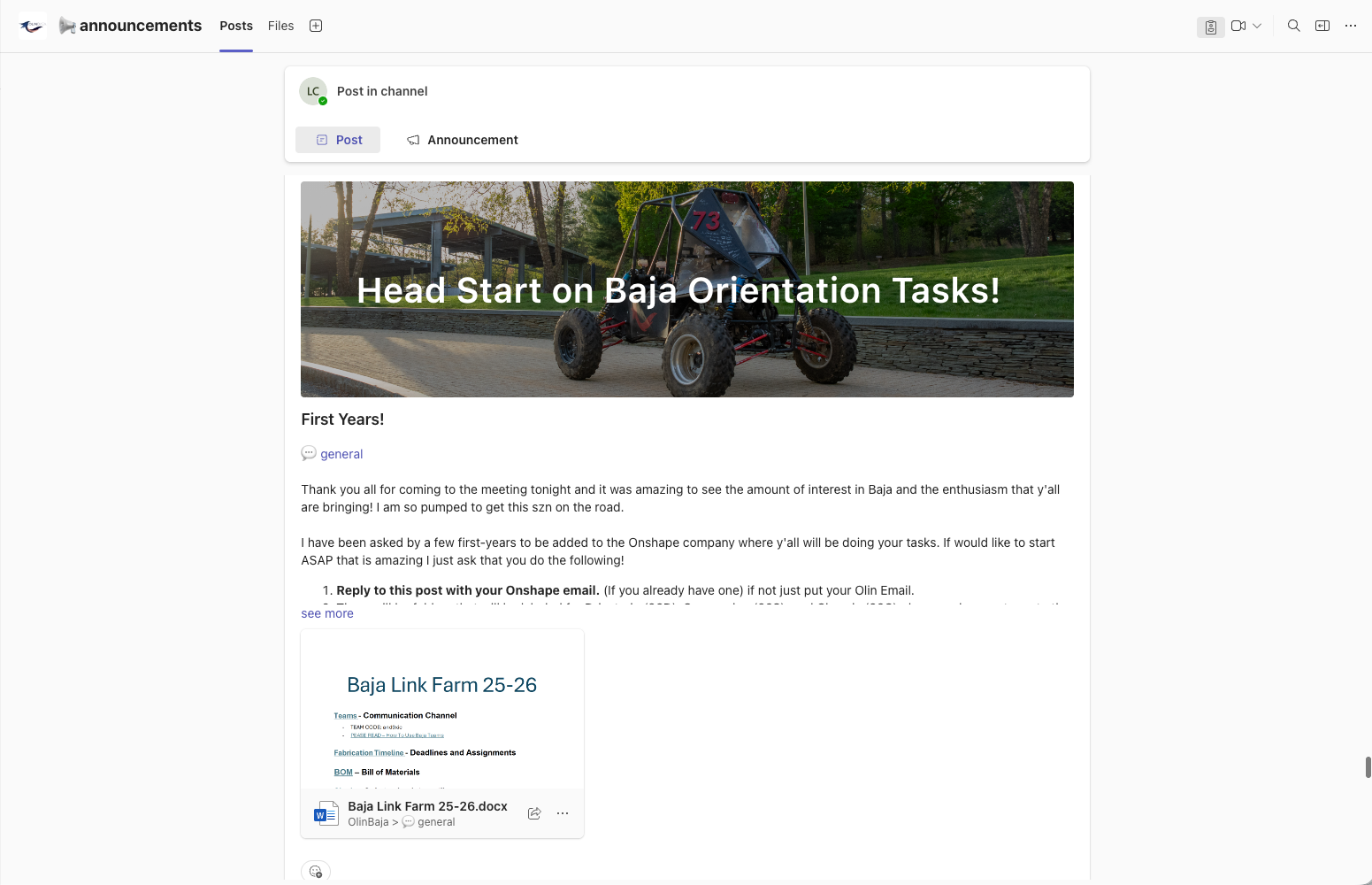

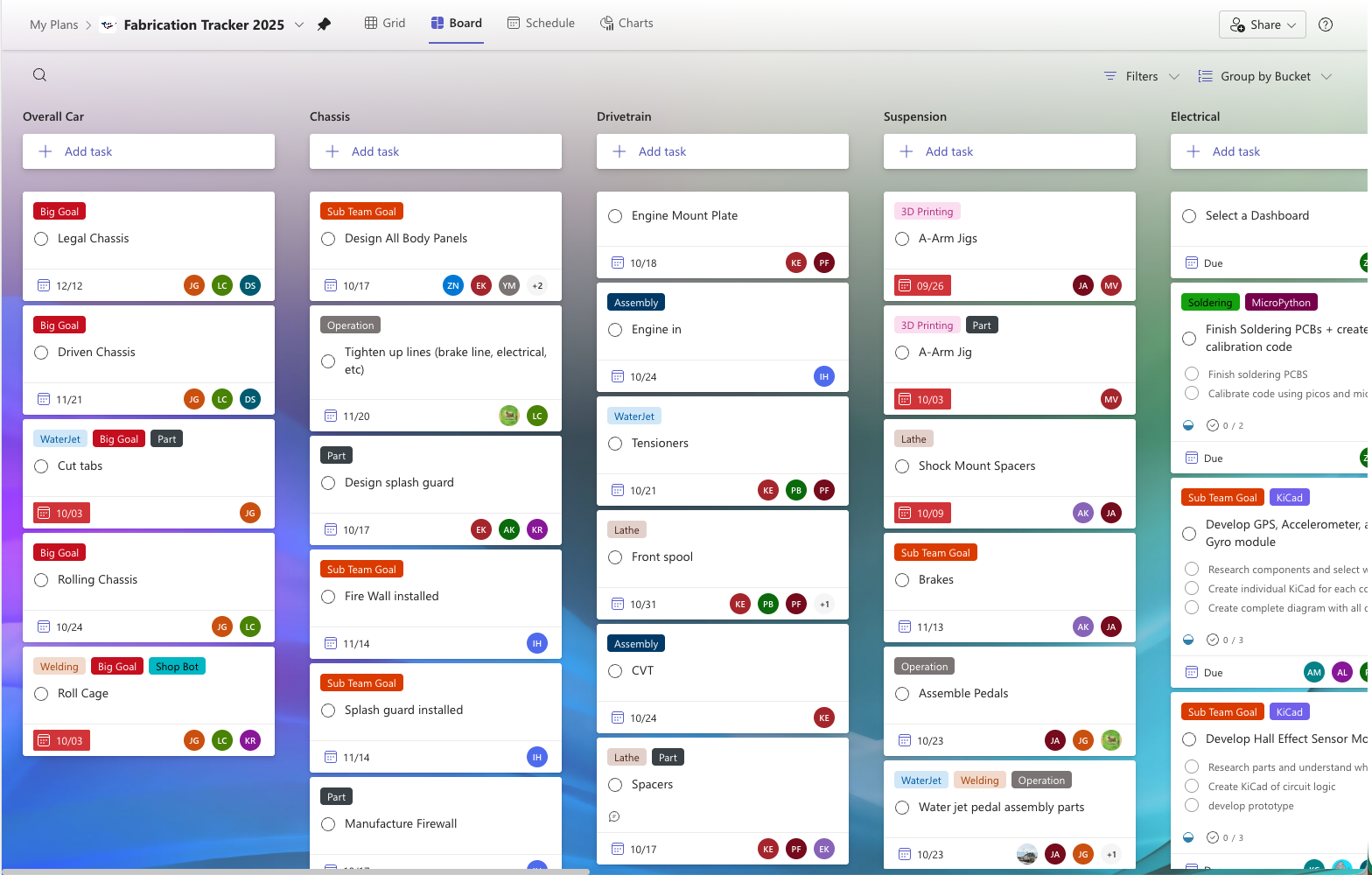

Leading Olin's Largest Engineering Project

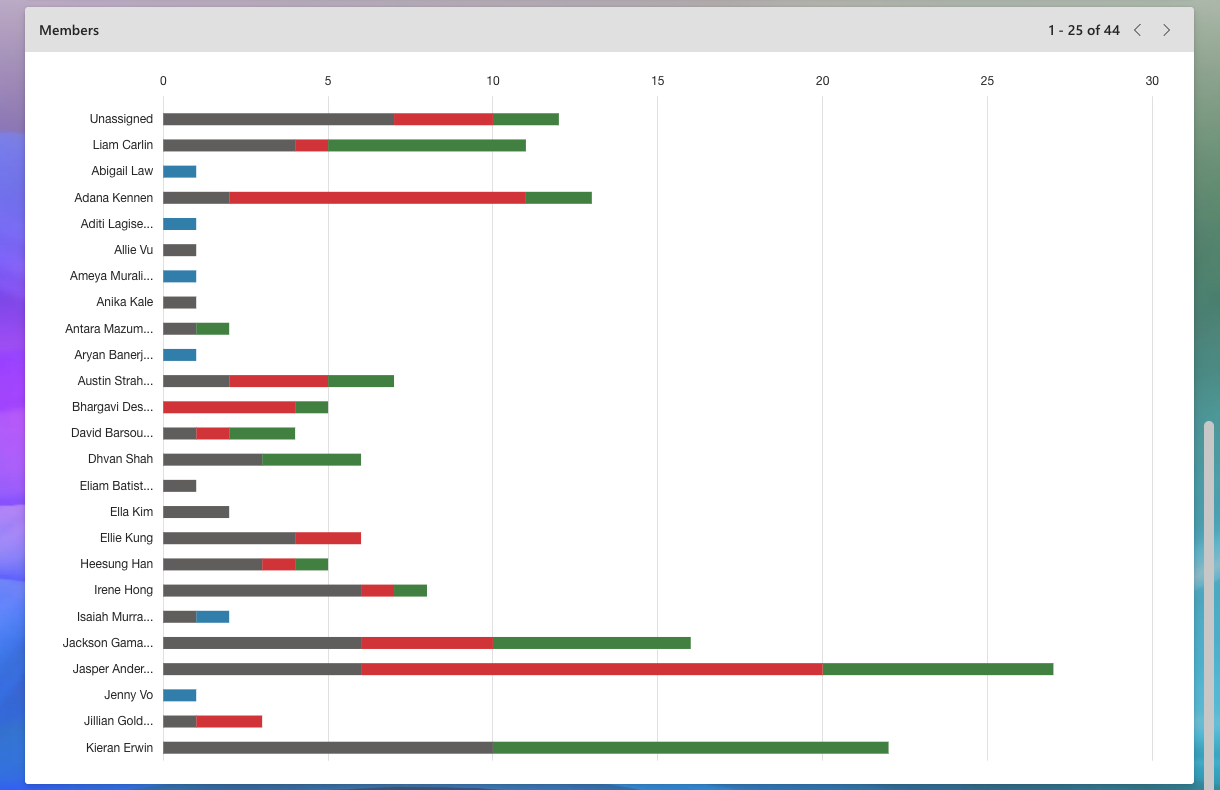

As Project Manager of the Olin Baja SAE team, I lead one of Olin's largest and most ambitious engineering projects — a team of more than eighty students working together to design, build, and race a high-performance off-road vehicle. The role combines engineering, leadership, organization, and culture building into one of the most rewarding challenges I've ever taken on.

The Olin Baja SAE team at competition